10-18, 2021 Oil Free Piston Air Compressor Oxygen Concentrators

● No Air Pollution, Maintenance Free, Ultra-quiet

● Built-in Thermal Protection Device

● Moisture Trap with Filter Cartridge

● Optional Vaccum Regulator

● Stronger Vapor-proof Capability

● DC Motor Optional

● Hi-tech Material for Key Parts

● Long service life, 24-month Pump Warranty

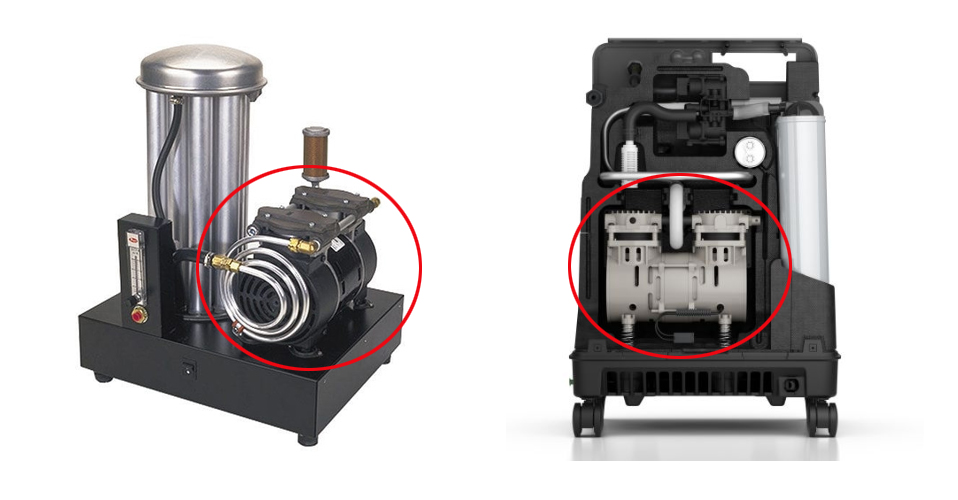

Due to the rugged quality and excellent performance as above, Pransch Rocking piston oil-less compressors were applied for some Workhorse oxygen concentrators,Workhorse Profile oxygen system, Emergency mobile system,Transportable Oxygen Concentrator etc. Pransch Rocking piston oil-less compressors allow these oxygen systems to be Compact and lightweight for maximum design flexibility, efficient, rugged, Low operating cost and for a secure running due to presense of oxygen.

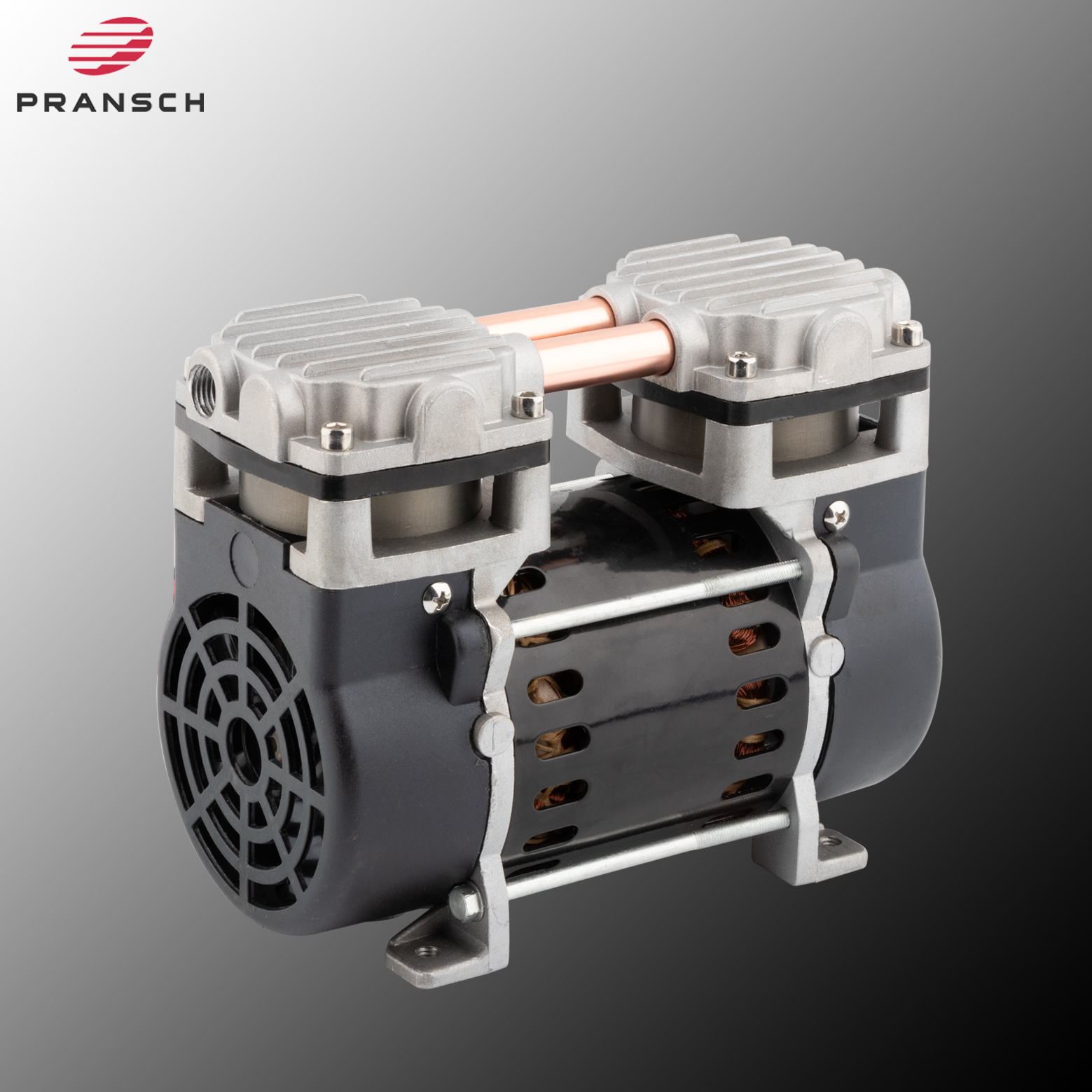

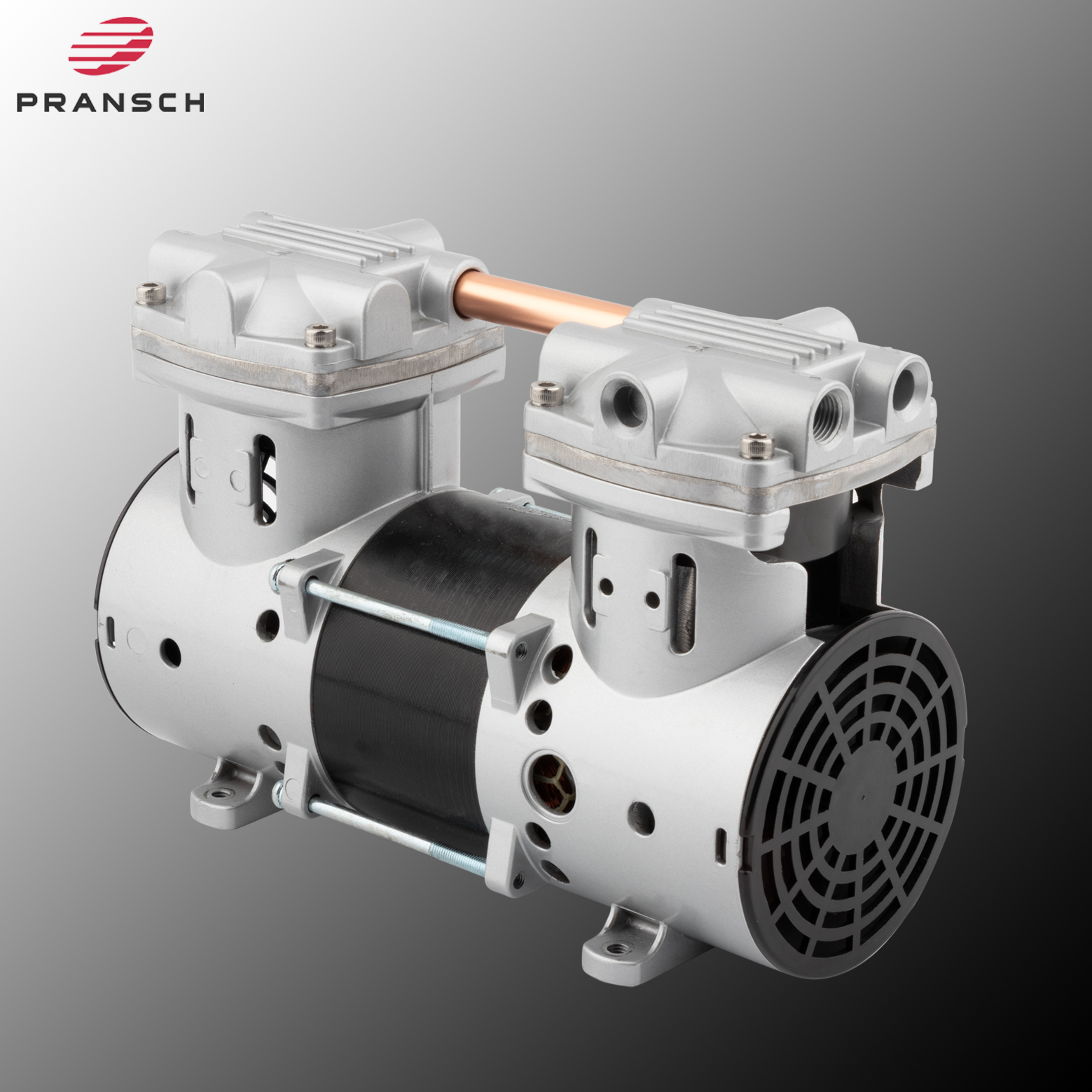

Pransch oil free piston air compressors have been applied to oxygen concentrators with different volumes of oxygen supply. Recommended models of Pransch oil-free piston air compressor for oxygen generators are: PM0300C, PM0550C, PM1000C, PM1500C, PM2000C, which can be continuously and stably running as air supply for oxygen concentrators. Air flow rate reaches 75~230L/min, pressure is able to go to 2.5~3.5 bar.

Pransch Oil less Piston Air Compressors guarantee long lifetime and constant suction performance even after many thousands of operating hours. The exceptional reliability of Pransch Piston Air Compressors is the result of our special focus on engineering. Pransch Piston Air Compressors impress many with their compactness and efficiency and also their safety in the workplace and their environmental contribution.

There are some dry piston air compressors of low quality and unstable air flow rate on the market, which is even more a medical disaster. PRANSCH has been in this industry for more than a decade, its excellent team and technical service are worth your trust.Contact Expert

For oxygen concentrators, below list of our mini rocking oil free oil-less piston air compressor corresponding models for checking:

PRANSCH ROCKING OIL-LESS PISTON COMPRESSOR PM0300C: for 2L oxygen concentrators.

PRANSCH ROCKING OIL-LESS PISTON COMPRESSOR PM0500C: for 3L oxygen concentrators.

PRANSCH ROCKING OIL-LESS PISTON COMPRESSOR PM1000C: for 5L oxygen concentrators.

PRANSCH ROCKING OIL-LESS PISTON COMPRESSOR PM1400C: for 8L oxygen concentrators.

PRANSCH ROCKING OIL-LESS PISTON COMPRESSOR PM1500C: for 10L oxygen concentrators.

PRANSCH ROCKING OIL-LESS PISTON COMPRESSOR PM2000C: for 15L oxygen concentrators

How Does an Oxygen Concentrator Work?

The 5 Step to summarized the Oxygen Concentrator Process.

1. Takes air from the room.

2. Compresses the oxygen.

3. Takes out nitrogen from the air.

4. Adjusts the way the air is delivered.

5. Delivers the purified air.

Oxygen concentrators use the surrounding atmosphere to create oxygen-rich air by sucking in the surrounding air and compress air to purify by removing nitrogen and other impurities. An oxygen concentrator is an air compressor that has an oilless piston air compressor, heat exchanger, surge tank, control circuit, humidifier, and gas pump with two cylinders filled with zeolite pellets and in which the pressure is balanced by a reservoir of valves and tubes. It sucks in air, extracts its nitrogen and leaves behind oxygen-enriched gas, which is often used by people in need of medical oxygen due to low oxygen levels in the blood.

The oilless piston air compressor constantly changes between the two sieve beds to ensure a continuous flow of air through the machine. The oilless piston air compressor compresses the air further into the first molecular sieve bed until it is saturated and filled with nitrogen. The compressed air then enters the first sieve bed, where the nitrogen is removed and the oxygen is forced back into the tank.

The oxygen concentrator compresses the air and passes it through the porous zeolite, whereby it adsorbs nitrogen from the air. The concentrator collects the remaining gases (oxygen and nitrogen) desorbed by the zeolites and reduces the pressure in the vent.

It takes some time for the oxygen concentrator to start cycling through the correct air concentration. In order to replenish the compressed air, the concentrator needs access to electricity and air. It is a two-cylinder air compressor filled with zeolite pellets, the pressure of which is equalized by a reservoir of valves and hoses. To get continuous pure oxygen it relays on batteries or electrical energy to filter the air and oxygen flow.

The classic oxygen concentrator uses a two-bed molecular sieve, but newer concentrators use a multi-bed molecular sieve. The two sieve beds work together to release oxygen to the cannula connected tank to release nitrogen and create a continuous loop that continuously produces fresh oxygen.

© 2018 Pransch Air Technology All Rights Reserved.